Here’s an introduction to spray foam roofing, which will cover these six points:

- What is spray foam roofing?

- How much does spray foam cost?

- What problems do spray foam roofs have?

- What roofing systems can spray foam be applied to?

- What are the benefits of installing a spray foam roof?

- What does a spray foam roof look like?

Let’s get started…

1. What is spray foam roofing?

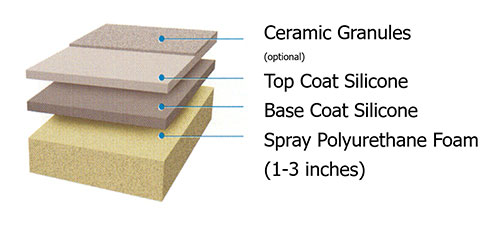

Spray foam roofing is a watertight roofing system that has three parts:

- Spray polyurethane foam

- Silicone coating (installed in two coats)

- Granules

The foam is produced by combining and heating two chemicals. These chemicals are pumped from a truck, transferred through a heated hose, and then sprayed onto an existing roof.

The foam increases in thickness by 30x, reaching a height of around 1.5 inches. The spray foam’s height (or thickness) is customized to every roofing system to create a slope for water to run toward drains.

Spray foam, by itself, gets damaged by UV rays from the sun. Therefore, a thin layer of silicone coating will be installed over the foam. The thickness of the silicone coating is usually around 20 – 30 mils.

The silicone coating is installed in two separate coats, where the topcoat will be embedded with granules.

The granules are there for added strength and traction for walking.

Here is a video of a spray foam roof application from start to finish:

Now that you know what a spray foam roofing system is (foam + coating + granules) let’s talk about how much it costs.

2. How much does a spray foam roof cost?

The cost of materials change daily. On average, a spray foam roof costs between $5 – $10 per square foot.

Here are other reasons why the price can go up or down, such as:

Location

The further away you are from a spray foam roofing contractor, the more expensive the project will be.

It will be more cost-effective if you’re close to a roofing contractor.

Existing roof condition

Suppose your roof is leaking, and it’s been letting water get under the top layer of your roofing system, which enters your insulation or deck. In that case, those saturated areas must be removed before installing spray foam.

If your roof is not letting much water in, then only a small portion of your roof will need to be removed before installing spray foam.

The more roof that needs to be removed, the more expensive your project will be.

Existing roof system

If you have a rubber roof, spray foam can be installed right over the top.

If you have a roof that’s held in place with gravel or stones (called a ballasted roof), those rocks and stones will need to be removed. Then since the roofing layer under those stones isn’t 100% stuck to the insulation, an adhesive or fasteners will need to be used to get that roofing layer 100% attached to the insulation. Then spray foam can be installed over the top.

You can see how different roofing systems require more or less work to prepare for a spray foam installation.

How tall is your building?

Suppose your roof is two stories high and easy to access. That will be much more cost-effective than the same roof 10 stories high in a downtown area where it’s difficult to access the roof.

Now that we know how much a spray foam roof costs, let’s get into the problems they can have.

3. What problems do spray foam roofs have?

There are three problems with spray foam roofs, they are:

Bad/Inexperienced Contractors Installing Foam

It’s sad to say, but there are some terrible spray foam roofing contractors. These contractors aren’t experienced in spraying foam. They use each roofing project they get as an opportunity to “see” if they can spray good foam.

There are many ways to tell a good spray foam roofing contractor vs. a bad one, but the first one is to show proof that you are certified with the SPFA. (Spray Polyurethane Foam Association)

One SPFA certification includes applicators spraying over 500,000 sq. ft. of foam.

Needs to be at least 50 degrees to apply

The temperature needs to be at least 50 degrees to apply spray foam. If you install spray foam in too cold of weather, the reaction of the two chemicals will be off, and the foam will not perform how it was designed to.

Overspray

Since the foam is very light, it can be carried away by the wind. To combat overspray, roofing contractors must cover nearby cars, use windshields, or spray out of an enclosed booth.

If foam lands on an area it wasn’t supposed to, it can be removed with car detailing. This is done by using a clay bar or letting the foam degrade on its own with exposure to UV rays.

Here is a video talking about spray foam and overspray:

4. What roofing systems can spray foam be applied to?

Some commercial roofing systems can handle spray foam, and some need some tweaking before spray foam can be applied. Let’s take a look:

Metal Roof

Spray foam can be installed right over a metal roof.

A rust inhibitor primer may be needed to stop oxidation if some of the metal is currently rusted.

One benefit of spray foam for metal roofs is that metal roofs have crimped panels, which leave tiny holes for water and air to enter/exit your building.

Applying spray foam makes your roof one continuous layer, covering these exposed areas.

TPO

Spray foam can be installed over a TPO roof if a cover board is installed first over the existing TPO.

It doesn’t matter if the existing TPO roof is fully-adhered or mechanically-attached; a cover board is always needed when installing spray foam over TPO.

TPO is slippery, so a cover board is needed to have the best possible adhesion.

EPDM

Spray foam can be applied to any of the three types of EPDM roofs: fully-adhered, mechanically-fastened, or ballasted.

For a fully-adhered EPDM roof, spray foam can be installed right over the top, as long as the EPDM is aged (more than 5 years old).

For a mechanically-fastened EPDM roof, a cover board must be installed first, then the spray foam can be installed over the top.

The rocks will need to be removed first for a ballasted EPDM roof. A cover board will need to be installed (because nothing holds that EPDM down once the rocks are removed), and then spray foam can be installed over the top.

Built-Up Roofs

Spray foam can be installed on a smooth or gravel-surfaced built-up roof since the roof is fully adhered to the underlying substrate.

For spray foam to be installed over a gravel-built-up roof, a wet-vac process must remove the stones and gravel so there’s a clean surface left behind.

Modified bitumen

Spray foam can be installed over an existing modified bitumen roof. Since “mod-bit” comes in a roll, whether they are torched or adhered down, it’s a fully-adhered system where a cover board isn’t needed.

Now that we know how each roofing system can handle a spray foam installation, let’s get into the benefits the system provides.

5. What are the benefits of a spray foam roof?

Here are five benefits of a spray foam roof:

Easy to install

It takes fewer roofers to install spray foam than conventional roofing systems (such as EPDM or TPO). It’s also sprayed over penetrations much faster.

A penetration (HVAC unit, pipe, curb, etc.) will take a conventional roofing system about 30 mins to roof around it; with spray foam, it’ll take about 2 minutes.

Energy efficient

Spray foam has an R-value of 6.6 per inch of thickness, the highest R-value per inch of any roofing insulation.

More R-value = Less heat/cool that escapes your building = lower energy bills.

Easy to maintain

If a spray foam roof gets a crack or a small hole, all you need to do is cut around the area, dry it out with a towel/rag, fill it with caulk, and smooth it out. On other roofing systems, the water will enter the insulation and travel horizontally, so you’ll have to remove a large section of your roof.

Seamless and waterproof

A spray foam roof has no seams, a popular area where water enters your roofing system. A spray foam roof is all one layer, so there are no opportunities for water to get into your roofing system.

If a spray foam gets a small crack or hole, the water will just sit in that area. Since spray foam is closed-cell, the water has no opportunity to move south into your system.

For water to enter a spray foam roof, a very sharp and heavy object would need to break through the granules, coating, and 1.5 inches of spray foam. This does not happen very often.

Renewable

After your initial 10, 15, or 20-year warranty expires, you can install a recoat.

A recoat is when you powerwash your spray foam roof clean and install new coating back to the original millage.

Say you have a 15-year warranty, which on year 1, gets a coating thickness of 25 mils. In year 15, you may be down to 7-10 mils.

To renew your roof, a contractor needs to power wash the roof, fix any small holes or cracks, and then apply new coating back to the original 25 mils with granules.

After, you’ll receive another 15-year warranty.

The foam never gets touched and never loses any performance.

This is how a spray foam roof is a renewable roofing system.

6. What does a spray foam roof look like?

Here’s a 30-second video of us spraying foam:

Here are a few photos of what a finished spray foam roof looks like:

Geauga County Board of Developmental Disabilities – Spray foam over an existing smooth built-up roof – 30,000 sq. ft.

Landmark Recovery – Spray foam over an existing gravel built-up roof – 23,600 sq. ft.

Sailorway Middle School – Silicone coating over an existing spray foam roof (also known as a recoat) – 56,100 sq. ft.

Let’s compare spray foam to other roofing systems

Hopefully, you learned the basics of spray foam roofing. We know it can be overwhelming and sometimes confusing to learn about a roofing system that most have never heard of.

Now let’s compare spray foam to the other traditional roofing systems. We’re talking about metal, coatings, and single-ply.

The eBook below discusses the pros and cons of various commercial roofing systems.