Quick Answer: Spray foam roofs require a recoat every 10-20 years because the coating that protects the foam from UV rays wears away.

Perhaps you’ve heard the term “spray foam recoat” but didn’t know what it means.

At first, you might think it’s a bad thing. Why would a spray foam roof need a recoat? Can’t it just last a long time on its own, as TPO and metal roofs can?

What if I told you that having the ability to be recoated is a colossal advantage cost-wise versus TPO and metal?

In this article, you’ll learn:

- The four parts of a spray foam roofing system

- What happens to the coatings over time?

- How is a spray foam roof recoated?

- Why having the ability to be recoated is a cost advantage over TPO and metal?

And just so you’re aware, West Roofing Systems has been in commercial roofing since 1979.

Many spray foam installs we’ve done in the 1980s and 1990s are on their 2nd and 3rd recoats.

This article has been reviewed, edited, and approved for publishing by a spray foam roofing expert with more than 30 years of experience.

Let’s get started!

What are the four parts of a spray foam roofing system?

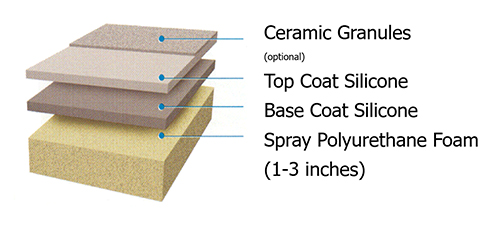

A spray foam roof has four parts:

- Spray polyurethane foam

- Basecoat of coating

- Topcoat of coating

- Embedded granules

After the roof is prepared to accept the spray foam system, the first part is to install the spray foam.

Since spray foam will degrade within 72 hours of UV exposure, the base coat of coating must be installed rather quickly. In most cases, spray foam and the base coat will be installed on the same day.

Once the basecoat has cured, a topcoat is installed. Before the topcoat dries, granules are embedded into the topcoat of the coating.

Now that you know the four parts of a spray foam roof, what happens to the coating over time?

What happens to the coatings over time?

Over the years, the coating will naturally wear away. Here’s a typical scenario:

Say you get a spray foam roof with a 15-year warranty. When the roof is installed, a 25-mil thickness of the coating will be installed over the foam.

When it’s year 15, approximately a 7-8 mil thickness of the coating will remain.

The coating gradually disappears with foot traffic, rain, snow, debris, and other weathering events.

The coating manufacturers have tested extensively to ensure their coatings outlast the warranty period.

Since we’ve been using coatings over foam roofs since we started as a company in 1979, the coating has never worn away before the expiration of a warranty period.

The coating will last the warranty period if no Acts of God or third-party damages exist.

Now that we understand how the coating is “sacrificial”, how does a spray foam roof get recoated?

How does a spray foam roof get recoated?

Once the warranty on a spray foam roof is expired, it’s time to begin the recoat process. The first step is to walk the roof and make any needed repairs.

Minor repairs, like any tiny cuts or punctures in the foam, will need to be sealed.

Then the roof can be power washed to remove any loose granules, dirt, etc. A clean environment is essential for the coating to adhere correctly.

Next is the building owner’s choice of how long a warranty they would like. Most options are 10, 15, or 20-year warranties. The more extended the warranty, the more coating that’s installed, and the higher the cost.

But once the building owner decides, the coating is sprayed or rolled onto the existing roof.

The contractor will take physical samples to ensure they install the correct coating thickness.

Suppose the warranty is going through the manufacturer of the coating. In that case, they will bring their inspector to check for several things, such as

- Is the coating installed thick enough to grant the desired warranty?

- Does the roof have enough slope to eliminate ponding water?

- Are all penetrations and flashings watertight?

Once the inspector is confident that the newly installed roof will surpass the warranty period, paperwork is signed, and the job is complete.

Now that we know the installation of a spray foam recoat, how is it cost-effective versus a roofing system that doesn’t need to be recoated?

Why is recoating a cost advantage versus other roofing systems?

When the warranty of a single-ply, built-up, or metal roofing system expires, most get 100% torn off. The cost to remove an entire roofing system and install another is pricey.

A recoat doesn’t require any tear-off.

Tear-off requires a significant number of labor hours. It also adds costs to the project because you transport all the materials to a landfill.

A recoat generally costs 33% – 50% of the original installation. To tear off and install another roofing system will cost 100% of the initial installation.

Conclusion

Now that you know all about recoating a spray foam roof, what other questions do you have?

Most building owners have asked these common questions:

- How much do spray foam roofs cost per square foot?

- What problems can spray foam roofs have?

- What are the pros and cons of spray foam, single-ply, and metal roofing systems?