You may have heard the term “spray foam scarfing” before.

But what is it?

Why does it need to be done?

How can a building owner with a spray foam roof prevent scarfing?

We’ll dive into each of these questions below.

To make sure you’re getting correct information here, I wanted to point out that West Roofing Systems has been scarfing spray foam roofs since 1979. And this article has been reviewed by our owners who have been spray foam installers, foremen, and salesmen for 30+ years.

Now let’s get into the meat of the article…

What is spray foam scarfing?

Spray foam scarfing is the process of removing saturated or damaged spray polyurethane foam off of a roof. This is usually done with a scarfer, which is very similar to a lawnmower.

Here’s a video of a scarfer removing spray foam in this video:

Scarfing is needed when there is a very large amount of saturation or damaged foam on a roof.

Why does spray foam scarfing need to be done?

Spray foam scarfing needs to be done because the spray foam roof has been damaged, meaning the coating and granules that are on the top layer have been damaged and water is coming into the foam.

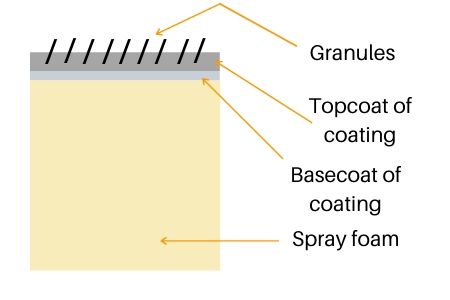

If you’re unaware of the layers of a spray foam roofing system, here’s a general idea of what it looks like:

The lines on top represent granules that are embedded into the topcoat (not the base coat) of the coating.

Somehow the coating and granules got a crack or were punctured, and the foam was exposed. UV rays will degrade foam 1/16th of an inch every year that it’s exposed to UV rays.

Also, the foam will be exposed to water.

While spray foam is closed-cell, meaning the water will not move laterally through the system (unlike other roofing systems which have insulation boards underneath the membrane), standing water will still degrade foam.

This is why it’s important to catch cracks and punctures as fast as possible so a simple repair can be made.

Most building owners do not have eyes on the roof, therefore they sign up for a maintenance package with the roofing contractor that installed the spray foam roof.

Maintenance packages cost around 3c per sq. ft. and get performed twice a year in the Fall and Spring.

A service team will walk the roof, identify all cracks and punctures, and will cut around these areas, dry the area out, and install caulk or silicone into the area. They will smooth the area out and it’ll be good to go!

Ignoring these cracks and punctures for months and years will destroy your roof, which will force a roofing contractor to scarf your foam roof when it’s next serviced.

How does a spray foam scarfer work?

A spray foam scarfer works like a lawnmower. It has 16” blades and it can be set to remove 1/2” or 1” of spray foam per pass.

Some spray foam roofs have 2 inches or more of foam. If this is the case, the scarfer will have to make multiple passes to eliminate all the saturated/damaged foam.

Once dry spray foam is reached, you no longer need to scarf that area.

NOTE: it’s important to know that most roofs (if not serviced routinely) can have a portion of the roof scarfed. For example, a 10,000 sq. ft. roof may only need 3,000 sq. ft. scarfed.

A scarfer will leave behind cut-up spray foam. Roofers will shovel the foam into trash bags which will be transported off the roof and into a dumpster.

How much does scarfing cost?

On a roof that needs to be recoated, a roof that needs to be scarfed first will cost approximately 20-30% more than a roof that does not need to be scarfed.

If you have a 20,000 sq. ft. roof, a recoat would cost approximately $33,333 – $50,000.

If scarfing is needed, adding 25% to the numbers above would make a recoat cost $41,666 – $62,500.

You could say that on a 20,000 sq. ft. roof, the scarfing portion of the recoat would cost between $8,333 – $12,500.

How does the scarfing process work?

When a spray foam contractor arrives on the roof, they will notice a roof with burnt-out foam. It will be black, like this:

If there’s water on the roof, this will need to be removed first. This is done by blowing water with high-powered leaf blowers into drains.

Drains will need to be checked to make sure they aren’t clogged.

NOTE: If there’s standing water on a spray foam roof, there’s a high probability the drains are clogged. This is because a spray foam roof is custom sprayed to certain thickness levels to create a slope towards drains so that there’s never any standing water.

Once standing water is cleared, and the roof is dry, the scarfer can begin making passes to remove the damaged foam.

After the damaged foam is removed, the entire roofing surface is power washed to create a clean, debris-free surface to spray new foam onto.

Once the foam is applied, new coating and granules are installed over top and you’ll end up with a roof that looks like this:

Maintenance plans and scarfing

We wanted to point out that the scarfing process is only needed when a spray foam roof gets damaged…AND it’s been left alone for years.

On spray foam roofs that have a maintenance package with West Roofing Systems, when performing a recoat, scarfing is rarely needed.

This is because we’ve kept a close eye on the roof and made all the repairs necessary before they turn into bigger problems.

On roofs that DO NOT have a maintenance package, the scarfing process is needed about 50% of the time.

That’s not the case with spray foam roofs installed by other contractors.

Other contractors may make a mistake by only installing one layer of coating over a spray foam roof. Doing so will leave your foam exposed to UV rays very quickly, which increases the risk of the roof degrading quickly.

The best thing a building owner can do is to sign up for a maintenance program.

This will save you time and money in the long run…as well as provide peace of mind that an expert is keeping a close eye on your roof.

Scarfing is an avoidable cost

Hopefully, you learned that scarfing a spray foam roof is something that can be avoided.

Besides the added cost, what makes it worse is that damaged spray foam gets contributed to landfills, which is bad for the environment.

Would you like to learn more about spray foam roofing?

West Roofing Systems has been in spraying foam on commercial roofs everywhere East of Mississippi since 1979, and over this time, we’ve had enough experience to develop this 8,000+ word eBook that you can view for free (and without providing any information).

This guide answers common questions, such as:

- How much does a spray foam roof cost?

- How often does a recoat need to be performed?

- What is the lifetime cost of a spray foam roof?