Everyone loves a roof that works how it’s supposed to, keeps the heat/cool weather in, and keeps leaks/water out.

But one of the most forgotten parts of every building is the roof.

It’s up high, it’s usually hard to get to, and it’s just something we hope works forever and ever, and we never have to worry about it.

But like most, we don’t worry about the roof until leaking happens. And with most commercial buildings having a rubber roof (about 70%), we’ll get into a solution most building owners haven’t heard of.

An SRM (Silicone Restoration Membrane) roofing solution can restore your rubber roof, get you a new 10- or 15-year warranty, and, of course, stop those leaks you have.

Let’s get started.

What is a silicone restoration membrane roofing solution?

A Silicone Restoration Membrane (SRM) is a fluid applied silicone coating sprayed directly onto an existing roof system.

A silicone roof coating is a single layer of silicone that’s rolled or sprayed on as a liquid to fill in cracks, blisters, and seams. The process does not improve the insulation or underlying system, but it does add an extra layer of protection from the elements.

How does the silicone restoration membrane solution get applied to a rubber roof?

Assuming a roofing contractor has already taken care of all the steps involved with preparing a rubber roof for an SRM, the next step is to clean the existing rubber.

You want to clean the existing rubber because it’s full of contaminants such as rocks and dirt. Also, carbon residue will be left behind after being broken down by UV rays over the years. You need to get rid of all that.

These contaminants need to be removed so the new silicone will adhere properly.

The first step in cleaning the existing rubber is to spray down EPDM Rinseable Cleaner, which will uplift all the contaminants.

The next step is to run a surface cleaner power washer, which will help the primer break down the surface on your rubber roof, so it gets clean.

The last step is to have a person rinsing the primer and contaminants away. This is very important! Skipping this step will cause an adhesion problem with the newly laid down silicone coating.

Most people think rubber is smooth, and it is when it’s new, but over the years, it’ll build a rough texture.

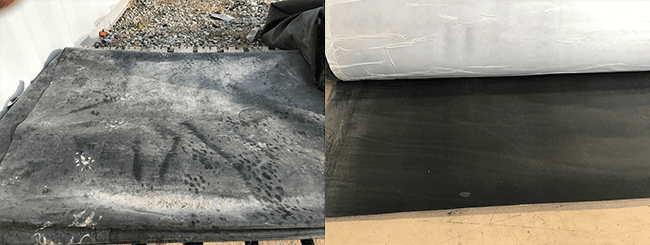

Here’s a photo of older rubber vs brand new rubber:

Now that the rubber roof is clean, you only need to prepare the seams and lay down the magic juice.

How do the seams on a rubber roof get reinforced?

There are two common types of seam reinforcement.

- Install a polyester reinforced mesh into a liquid top coating and then an additional silicone coating after the topcoat has cured.

- Use a self-adhering, reinforcing tape that would receive a liquid topcoat.

How does the actual silicone get applied?

The silicone membrane is sprayed on or roller applied over the entire surface of the roof. Different manufacturers require different coating thicknesses. In some cases, only a single layer is required, which saves additional dollars in reduced labor costs.

How does the warranty work with a Silicone Restoration Membrane roofing solution?

After the silicone coating membrane has been completed, a final inspection will be performed by a third-party or the manufacturer’s representative to verify all the necessary repairs were performed properly and the silicone is applied accurately.

When the repairs and silicone membrane coating are approved, the final warranty is issued.

Most warranties are 10-yr, but we’ve seen 15-yr warranties granted as well.

Most building owners don’t know about the silicone restoration membrane solution

SRM’s have only been around the past 3-5 years. When most building owners have a leak, they usually repair and repair, and when they realize they’re dumping too much money into continuous repairs, they replace the roof.

You don’t have to do that!

If you keep up with your rubber roof repairs, or are enrolled in a preventative maintenance and repair program, after 15 or 20 years, when the rubber isn’t performing the way it should, you have the option to apply silicone over top and get a new 10-15-year warranty.

There are so many benefits of a SRM roofing solution it’s unreal.

If you’d like to learn more about SRM’s, please download our cheat sheet below: