Someone visited our site and downloaded “The Essential Guide to Spray Foam Roofing.” This eBook answers basic questions about spray foam roofing, such as:

- How much does it cost per square foot?

- What common problems the spray foam roof system has?

- How long the spray foam roof system will last?

Etc.

But I guess the guide wasn’t detailed enough.

They reached out and had this comment:

“What about UV protection? How many mils thick is the final product? What colors can it come in? And what is the additive to stop slipping?”

Below are my responses.

NOTE: A spray foam roofing expert with over 30 years of experience has read, edited, and approved this article for publishing.

Let’s get started!

UV Protection

Spray foam will degrade when exposed to UV rays within 72 hours.

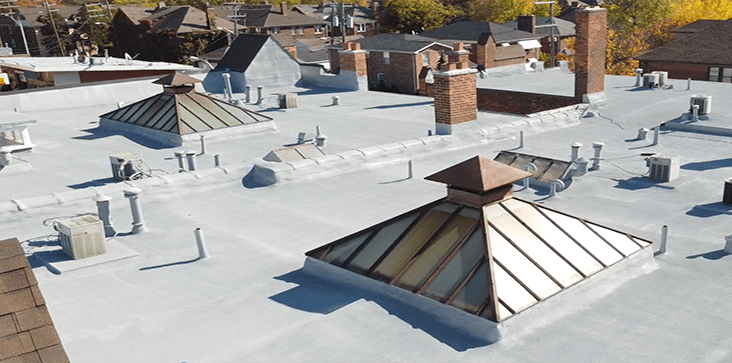

Every spray foam roof has an elastomeric coating installed over it. Coatings come in Urethane, Silicone, and Acrylic. We use silicone 99.9% of the time because it’s the best bang for the buck in terms of price and performance.

Here is a short video showing silicone coating being installed over freshly installed spray foam:

The thickness of the final product

The typical application is an average of 1.5 inches of spray foam (1” at drains/penetrations and 2” around the perimeter) and 20-30 mils of coating on top of that.

The warranty length is determined by the coating thickness. 10-year warranty = 20 mils. 15-year = 25 mils. 20-year = 30 mils.

Spray foam must be installed at a minimum of 1” thickness to perform to its max.

There are instances where a minimum R-value is required by building codes, such as new construction.

For example, in Ohio, the roof on any new building must have a minimum of an R-25. Spray foam has an R-value of 6.5 per inch of thickness. For this scenario, roughly 4 inches of spray foam would be installed.

Colors

All the top manufacturers produce any color of coating or granules you want. We’ve done red, blue, and blends of many colors to make a unique color for clients. The most common colors are grey and white, but a good contractor and manufacturer can create anything you’d like.

Additive for slipping

Yes, coating on its own can be slippery, so (if desired) we install embedded granules into the top coat of coating.

For example, say you want a 10-year warranty. The foam is installed, and then the base coat of coating is installed at 10 mils thick. Let the base coat of the coating cure. Then install the top coat of coating at another 10 mils thick with embedded granules.

If you’d like to see the granules embedded into the top coat of coating, please click on the link in the conclusion.

Conclusion

As with many things, it’s best to show how things work through a video.

This video of a spray foam roof installed from start to finish shows the foam, base coat of coating, top coat of coating, and granules embedded: