So, you heard that a spray polyurethane foam roof is sustainable and renewable?

It’s true.

West Roofing Systems installed a spray foam roof at the Playhouse Square in Cleveland, Ohio in 1972. Since then, the roof is still going strong (sustainable), and it’s been recoated (renewable) three times.

How does this happen?

In today’s article, you’ll learn:

- How is a spray foam roof sustainable?

- How is a spray foam roof renewable?

- How does being sustainable and renewable affect the environment?

- How does spray foam compare to other roofing systems?

Most people have never heard of a spray foam roof before. At West Roofing Systems, when we explain that the roof is sustainable, renewable, and the last roof you’ll ever have to install, their ears perk up.

They think “The last roof I’ll ever have to install, how does that work?”

Let’s explain how a spray foam roof is sustainable and renewable.

How is a spray foam roof sustainable?

The definition of sustainable is: “able to be maintained at a certain rate or level.”

A spray foam roof can be easily maintained to last as long as the warranty period (which is usually 10,15, or 20 years).

All you need to do is keep an eye on the roof throughout the year and the roof will last.

We recommend having a roofing contractor get on your roof once or twice per year.

Some of the benefits of using a spray foam roofing contractor for maintenance is:

- Safety. They will have trained personnel on your roof. Plus, you won’t have to worry about anyone on your staff getting injured.

- The contractor will have records of your roof and will know what to look for year after year.

- Contractors can identify anything that could be wrong with your spray foam roof.

During a maintenance inspection, a contractor will inspect the roof to see if there are any holes, cracks, or punctures.

If there is, they will cut around the crack, dry the area out, insert caulk or coating, and smooth the area out.

It’s that simple.

A problem that can happen is when a spray foam roof is ignored for years without anybody checking on it.

Maybe flying debris caused a tiny hole in your roof. Maybe the HVAC contractor dropped a few screws and stepped on them, making a small crack in the roof.

If these areas aren’t repaired, the UV rays could damage the roof if any spray foam is exposed to the sun.

But as long as an eye is kept on the roof (that goes for any roof), the roof will never lose any of its insulation or waterproofing qualities.

NOTE: There are some roofs we sprayed in the ‘70s and ‘80s that still have the original foam on them. As long as maintenance is kept up, spray foam roofs are very sustainable.

How is a spray foam roof renewable?

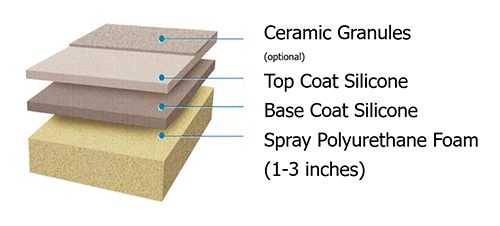

On a spray foam roof, three different materials are installed: spray foam, coating, and granules.

Material #1 is the spray foam. This is installed at least 1” thick and varies in thickness per R-value and sloping requirements.

Material #2 is the coating. The coating protects the spray foam from UV rays and adds another waterproofing layer. The coating is installed in two coats and ranges in thickness from 20 – 30 mils.

Material #3 is granules. Granules are embedded into the top coat of the coating. This increases the strength of the spray foam roof.

An example of how a spray foam roof is renewable?

Let’s say you got a spray foam roof, and it came with a 20-year warranty.

A 20-year warranty means that 30 mils of coating (with granules) will be installed over the spray foam roof.

Over time, the coating will wear away by natural causes (foot traffic, weathering, dirt, debris, etc.).

In year 20, the thickness of the coating might be around 7-8 mils.

What happens once the warranty has expired is what’s called a “recoat”.

The recoating process includes:

- making any necessary repairs

- power washing the roof clean

- installing coating back to the original installation’s thickness

In the example above, if you choose another 20-year warranty, the coating would be brought back to 30 mils.

Once the coating and granules are installed, the manufacturer of the coating or the roofing contractor will inspect the roof to make sure the thickness of the coating is correct.

Once that’s confirmed, you get a new 20-year warranty.

The process can repeat over and over again.

NOTE: When someone says that a spray foam roof can be the last roof you ever install on this building, now you know how that happens.

How does being sustainable and renewable affect the environment?

With a spray foam roofing system, there are no contributions to landfills.

After 20 years, the spray foam doesn’t wear away, it doesn’t need to be removed, and it doesn’t lose any performance.

The coating and granules wear away naturally. After 20 years, an estimated 20-25 mils of coating would wear away.

How does spray foam compare to other roofing systems?

When the warranty ends on a single-ply, metal, BUR, or any other type of roofing system, the roof is 100% removed and transported to a landfill.

Not only is this bad for the environment, but it’s costly to the building owner.

Roof tear-off is expensive because:

- it’s labor-intensive

- you must pay to transport those materials to a landfill

- then you have to pay to install a brand-new roofing syste

Case Study: Playhouse Square

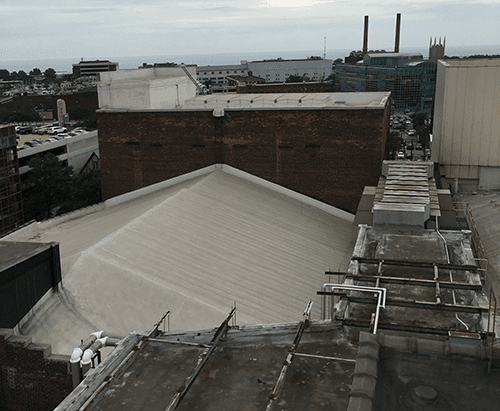

Playhouse Square’s spray polyurethane foam roof was installed in 1972 and has been recoated 3 times!

In 2022, it’ll be 50 years since the initial installation!

Here’s the link to the complete case study of Playhouse Square.

What to learn the basics of spray foam roofing?

Please check out our cheat sheet, which explains:

- How much a spray foam roof costs?

- What problems do spray foam roofs have?

- What benefits (besides being sustainable and renewable) do spray foam roofs have?