Since typical membrane roofing does not include the insulation factor, as a customer, you have more options to choose from to insulate your facility’s roof. There are a few types of insulation options the facility manager/owner can choose from:

- Polyisocyanurate (Polyiso)

- Extruded Polystyrene (XPS)

- Expanded Polystyrene (EPS)

What is a Roofing Membrane?

A roofing membrane is the top waterproof layer of roofing. The membrane is the layer to keep water and other weather out. The insulation underneath the membrane insulates the building.

Roofing membranes can be made out of a variety of materials:

- Synthetic Rubber

- Thermoplastic Membrane

- Modified Bitumen

Rigid Foam Insulation Installation

Prepare Roof Deck

The roof deck or substrate is the bottom layer of a single-ply membrane roofing system. The roof deck can be plywood, metal, concrete, or wood planks. The first step with roof installation is to prepare the roof deck by removing all dirt, dust, and contaminants. This can be done with air pressure, vacuuming, or even sweeping.

Cut to Size

After the roof deck is prepared, the rigid foam boards need to be cut to size to fit snugly together on your roof. Rigid foam is produced in various size panels (4 ft x 8 ft, 4ft x 4ft, etc.). The boards must fit together tightly to help prevent warm air from leaving the top of the building.

Attach to Deck Board

After the roof deck is ready, the rigid foam insulation is installed. Depending on the type of insulation you choose and the desired R-Value you want for your facility, you may need to build up a few insulation layers. The R-Value is a measurement of heat loss and heat gain. A higher R-Value means a higher ability to retain or keep heat out of a facility.

The National Roofing Contractors Association (NRCA) suggests installing at least two layers with staggered seams. The layers are screwed down or adhered to the underlying roof deck, and the seams on the insulation board’s top layer are taped to protect against water.

Types of Roofing Membrane Insulation

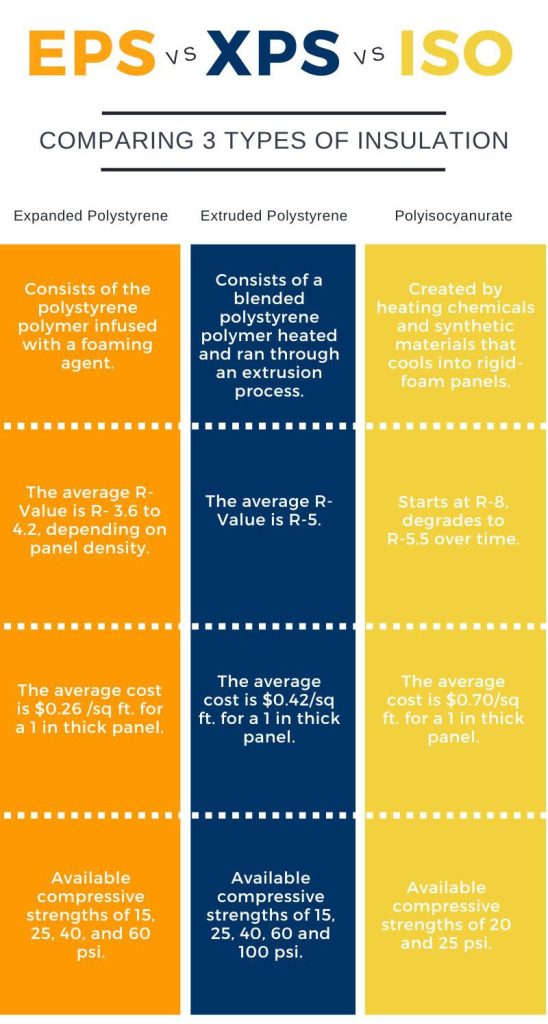

NOTE: scroll below if you’d like to view an infographic comparing the three types of insulation

Polyisocyanurate

As the most used insulation type for roofing applications, Polyiso is a closed-cell foam created by heating chemicals and synthetic materials into a composite material that cools into rigid-foam panels. Closed-cell foam indicates that all the cells are enclosed, not connecting with other cells or combined with air.

The average cost of polyiso insulation is $0.70/sq ft. for a 1” thick panel. When installed, the R-Value starts at R-8 and degrades down to R-5.5 over time (Cold-Weather Performance of Polyisocyanurate).

Extruded Polystyrene (XPS)

Usually defined by the blue, green, or pink color, XPS falls between Polyiso and EPS in the range of price and performance. Extruded polystyrene is a blended polystyrene polymer heated and ran through an extrusion process. (Facilitiesnet.com)

XPS is semipermeable with a perm rating of 1. The average cost of extruded polystyrene insulation is $0.42/sq ft. for a 1-inch thick panel. The average R-Value is R-5.

Expanded Polystyrene (EPS)

With the highest R-value per dollar, EPS is used for roof, wall, and floor insulation. EPS can be used for ground contact and does not retain water over time.

Expanded polystyrene consists of the polystyrene polymer impregnated with a foaming agent. The material expands when exposed to heat and is molded into a uniform, closed-cell insulating material. (Facilitiesnet.com) Commonly known as beadboard, EPS is also used to manufacture products like coffee cups.

The average cost of expanded polystyrene insulation is $0.26 /sq ft. for a 1-inch thick panel. The average R-Value is R- 3.6 to 4.2, depending on panel density.

Here is an infographic simplifying the data:

Ready to learn more about commercial roofing?

The guide below gives you the pros and cons of the most popular roofing systems out there, including:

- Single-ply

- Metal

- Spray foam

- Roof coating systems

- Bult-ups

- Shingles