Let’s say you’d like to get a spray foam roof, but you don’t know how long the job’s going to take.

Maybe you manage a theatre and you’ve got plays sprinkled in the schedule the next few months. You’re not going to wait until a large gap in your schedule to get your roof done.

You have a roof that’s leaking and business that needs to be done in order to keep things going.

So, how much of a gap does a spray foam roofing contractor need?

Depending on many factors, a roofing contractor aims to shoot 2500-3500 square feet of finished spray foam per day.

Depending on how many square feet your roof is will depend on how long the job will take.

However, there are MANY other factors that affect how long a spray foam roofing job will take, such as:

- Temperature

- Roof Complexity

- Thickness of Foam

- Number of Penetrations

- Wind

How does temperature affect how long a spray foam roofing job takes?

Have you ever ran a mile in 8 minutes, and the next day, you ran the same mile in 10? What changed? One variable could be the temperature outside (or your hangover, tired legs or bad chili).

Labor on a spray foam roof is no different.

A perfect spraying day is 70 degrees in the morning and 75 degrees at night. Now that rarely happens in Ohio, but once the heat gets into the 80’s, the sun starts taking a toll on the guys.

And that’s just air temperature. We’ve been on black rubber roofs this summer that were registering 192 degrees Fahrenheit.

The hotter it is, the more it just beats on you. And that increasing temperature will slightly slow down a spray foam roofing job.

How does roof complexity affect how long a spray foam roofing job takes?

I have a 1998 Honda Prelude; my friend has a 2019 Subaru Forester. His oil filter is literally on top of the engine. Pop the hood and you’re there.

Mine, I need to jack the car up, put down jack stands and get on the ground to see my oil filter. You can see the difference in time it takes to complete the exact same task.

Complexity on a spray foam roofing job is no different.

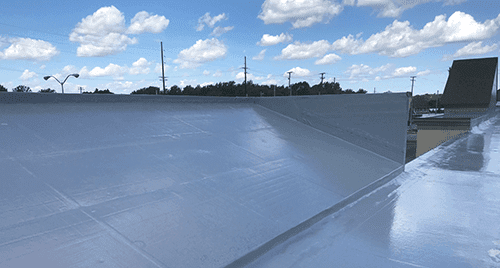

We’ve seen roofs that are completely flat. All you need to do is show up and pull that trigger until you’re done (obviously it’s slightly more complicated than that).

Other jobs have different forms of preparation at every roofing section.

Some jobs have walls, sloped/raised roofs, valleys, roofs on completely different levels, etc.

A flat, spray foam roofing job can be done 3-4x faster than a more complex roof with the same square footage.

How does the thickness of foam affect how long a spray foam roofing job takes?

This one’s simple. I can even hold the personal story on this one.

The more foam that’s sprayed on, the longer a job will take.

Most spray foam roofing jobs get laid down 1.5” or 2” thick, depending on the R value the owner expects upon completion.

Does the number of penetrations affect how long a spray foam roofing job takes?

Absolutely. It’s like the trip to grandma’s house. It takes 20 minutes with no traffic, 35 minutes if there’s an accident, you got caught in a couple lights, whatever the interruption may be.

Same thing happens during a spray foam roofing job.

But instead of traffic lights and accidents, what slows down a foam roofing job are what we call penetrations.

Penetrations are anything that comes through the roof. Examples are:

- HVAC units

- Skylights

- Vent Pipes

- Drains

The more penetrations, the more time it takes to work around these elements.

How does wind affect how long a spray foam roofing job takes?

Wind can greatly increase the length of time of a spray foam roofing job because of over spray. How would you like to park near a building, do what you have to do, and you come out and your car has white spots all over it?

To combat wind, a roofing contractor will use a windscreen. The person who holds the windscreen could be one extra person spraying down foam.

Wind can also affect the time it takes to lay down silicone coating on top of the foam. If there’s little to no wind, silicone can be sprayed on (fastest application time) or, if there’s enough wind to cause over spray, silicone will have to be rolled on (slowest application time).

Before any spraying starts, if the wind is going to produce over spray, a roofing contractor will suggest the building employees move their vehicles to another parking lot. If that’s not possible, the crew will put car covers on, which adds time to the project.

As you can see, wind has a MASSIVE impact on how long a spray foam job takes to complete.

The fastest spray foam roofing job ever

In 1997 (when the Tribe should’ve won the world series), we sprayed 1.3M sq. ft. of foam on a Chicago building. We did the job in 4 months, with 4 rigs and 37 guys.

Now that’s moving!

Who says they call Chicago the “Windy City”?