A self-flashing roof is when the top layer of a roof doesn’t need fasteners, adhesives, or rocks to be secured to the insulation or deck below.

There are only two examples of a self-flashing roof.

- Spray polyurethane foam roofing is fluid-applied that expands 30x in size within seconds. The foam will cure, harden, and bond with the surface below.

- Elastomeric roof coating systems (silicone, urethane, or acrylic) are fluid-applied as well. These coatings are super thick paint that’s engineered to withstand weathering elements. The coating is spray-applied or rolled…and will adhere to the surface below.

So why does this matter?

Or what are the benefits of having a self-flashing roof?

In this post, you’ll learn:

- The problems with fasteners

- The problems with adhesives

- The problems both of them have in general

- The benefits of a self-flashing roof

And just so you’re aware, every article written at West Roofing Systems has been reviewed and edited by a commercial roofing expert with more than 30 years of experience.

West Roofing Systems has been in commercial roofing since 1979.

Let’s get started!

The problems with fasteners

Fasteners are needed to secure roofing membranes, such as metal, TPO, and EPDM to the insulation or roof deck below.

Problem #1 – fasteners can back out

A roof expands and contracts with fluctuating roof temperatures.

A roof can be 180 degrees on a hot sunny day. That same roof can cool down to 60 degrees at night. That’s a 120-degree difference in temperature.

This expansion and contraction happens every day, year after year. Over time, fasteners can back out and create an immediate water entry point.

Problem #2 – fasteners can create thermal bridging

Since fasteners go through the top layer of a roof and the insulation, it creates an opening for air transfer.

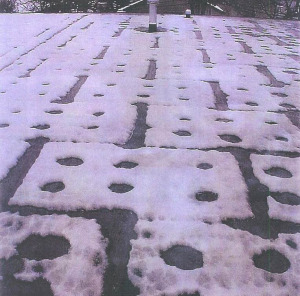

Take a look at this image below, brought to you by Progressive Materials:

You can see where the heat has escaped the roof and melted the snow.

The problems with adhesives

Adhesives are used to secure a membrane to a penetration. For example, an HVAC unit gets in the way of rolled out TPO.

Custom cutting, termination metal, and sealants might have to be used to install a single-ply roofing system around pipes, skylights, HVAC units, drains, and anything that comes through the roof.

The problem is that adhesives are expensive. When you’re trying to reduce the cost of your roofing project, adhesives don’t help.

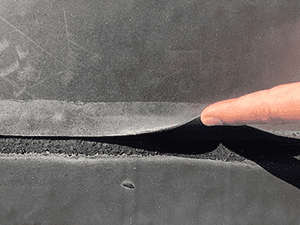

Another problem is that adhesives can wear out. We’ve talked about the abuse a roof can take with expansion and contraction over the life of a warranty, which can be 10-20 years.

If not installed properly, exposed adhesives can dry out from UV rays. When adhesives wear out, the membrane loses adhesion to the penetration and creates a water entry point.

The problems fasteners and adhesives have in general

Problem #1 – Hard to find

As of June 2022, we’ve noticed fasteners and adhesives are very hard to find. One building owner reached out to us looking for a TPO roof, but was looking for an alternative because these products weren’t available until 2023.

Of course, things change and the materials can suddenly become widely available, but as of now, they are hard to find.

Problem #2 – Labor error

Fasteners and adhesives have been used for decades and decades and will work great to create a watertight roofing system.

The problem is that they need to be installed properly.

Make sure to choose a roofing company that you can trust. One thing I would do is ask a contractor for a list of case studies or reference lists that you can call.

See if they have roofs that are leak-free for 10+ years!

The benefits of a self-flashing roof

Benefit #1 – Easier and faster to install

When a contractor is installing a spray foam or a roof coating system, the installation process doesn’t change once a penetration is met. The sprayer sprays around the penetration and keeps on going.

An HVAC unit may take a spray foam installer 1-2 minutes to spray around. An HVAC unit may take a single-ply roofing installer 30 minutes to make the area watertight.

Some roofs can have hundreds of penetrations. The amount of time it takes to install a roof around penetrations can greatly affect the labor hours of a project.

Installing a self-flashing roof is easier and faster than traditional roofing systems.

Benefit #2 – No seams

Traditional roofing systems roll out sheets of material and piece them together to make a watertight roofing system.

The problem is that the seams need to be attached perfectly.

Contractors:

- Heat-welded the seams together

- Use fasteners and adhesives to piece sheets together

- And/or use rocks to hold sheets of roofing material together

The problem is when the roof fluctuates with the temperature changes, a large amount of stress is put on the seams.

Going with a seamless, self-flashing roof system eliminates the possibility of a seam coming apart.

Benefit #3 – No thermal shock

Thermal shock is the damage that can occur when the roofing material on your building expands and contracts in a short period of time in response to temperatures rising or falling too fast.

If your roof is made up of several different materials, each part could expand and contract at different rates, causing damage.

Metal and membrane roofs are prone to thermal shock, as it causes them to move slightly, which opens up seams over time.

Benefit #4 – Not reliant on unavailable materials

As stated before, fasteners and adhesives are hard to find. A self-flashing roof doesn’t need these for the roof to be installed correctly.

Conclusion

Hopefully, you learned some of the problems with fasteners and adhesives, as well as the benefits of a self-flashing roof.

I wanted to point out that fasteners and adhesives have been used for decades and can produce a watertight roofing system that lasts a long time. Special attention just needs to be taken on the installation.