Summary: A seamless roofing system doesn’t use fasteners or adhesives. There are two kinds of seamless roofing systems: spray polyurethane foam and roof coating systems.

Someone reached out to us in January 2022, saying:

“We are trying to explore different options as fasteners and adhesives for TPO and EPDM have lead times until early 2023.”

If you need to install a commercial roof before 2023, what are you supposed to do?

In this article, you’ll learn the basics of two seamless commercial roofing systems:

- Spray polyurethane foam

- Roof coating systems

You’ll learn what they are, the pros and cons, how they are installed, and what warranties come with them.

Just so you’re aware, we only write articles based on true events and experiences. Every piece of content written at West Roofing Systems is produced in-house. Every article is reviewed and edited by a roofer/salesman with 30+ years of experience in the field.

West Roofing Systems has been specializing in spray foam roofing systems since 1979. Roof coating systems began being installed as their own “roofing system” around 2008.

Let’s get started!

Spray Polyurethane Foam (SPF) Roofing Systems

Spray Polyurethane Foam Roofing is a material that’s sprayed as a liquid so it can expand into a foam, creating a solid layer across an existing roof.

The chemicals, A (polyol/resin) & B (isocyanate), are pumped from separate containers through heated, high-pressure hoses to an internal mixing spray gun.

What comes out of the gun is a liquid that expands 30x its size within seconds. The usual height/thickness of spray foam is around 1.5 inches.

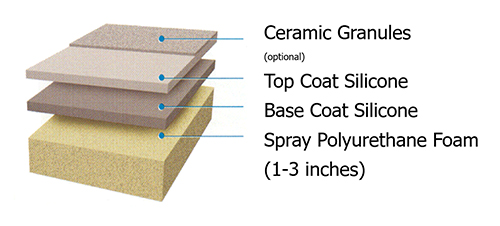

There is a base coat of coating that goes over the foam to protect it from UV rays. The topcoat of coating is installed with granules embedded into it.

Since spray foam self-adheres to whatever it’s sprayed onto, there are no fasteners or adhesives needed!

Roof Coating Systems

Roof coating systems are comparable to putting very thick paint onto your existing roof. Of course, the “coating” is engineered for commercial roofing, meaning it’s waterproof and can expand and contract with the roof and not lose any performance.

Roof coatings are sometimes referred to as “elastomeric” or “restoration membrane”. There are three main types of coatings:

- Urethane

- Silicone

- Acrylic

Each of them has its pros and cons. We’ve found the best bang for the buck is with silicones.

Since roof coating systems are fluid-applied and can adhere to any roofing membrane, there are no fasteners or adhesives needed.

Pros of a spray foam roof

- Completely seamless – spray foam roofs have no seams, which eliminates the most common area where roofs leak.

- Self-adhering – spray foam roofs can adhere directly to metal, built-ups, and torch downs. Spray foam needs a coverboard when spraying onto single-ply roofs.

- R-value – Spray foam has an R-value of 6.5 per inch of thickness. This is the highest R-value of any roofing insulation. You should expect your energy costs to drop after a spray foam installation.

- Renewable – Spray foam roofs are protected from UV rays with roof coatings. Once the coatings wear away, the roof can be cleaned, and more coating can be installed. The foam doesn’t lose any R-value or performance over time.

Cons of a spray foam roof

- Bad contractors – there are some bad contractors installing spray foam the wrong way. When the roof fails, the roof system gets the blame, not the contractor. It’s very important to choose a contractor that’s been spraying foam a long time and has a client list of successful projects.

- Overspray – spray foam is very light and therefore can be taken by the wind and carried onto cars, windows, buildings, etc. Contractors will use windscreens or spray foam out of a 100% enclosed booth, or not spray foam at all that day, but overspray is a problem that only SPF has.

- Limited Installation Window – it needs to be at least 50 degrees to install a spray foam roof. If it’s under 50, the chemistry with the foam materials won’t be right and the product will be inferior.

Pros of a roof coating system

- New warranty – once the roof is properly prepared and a roofing coating system is installed, a new warranty is granted (usually 10, 15, or 20-years)

- Self-adhering – a roof coating system can be applied to any roofing substrate without the use of fasteners or adhesives. Although on non-smooth surfaces, coating applications do not eliminate ponding water. Other additional materials can be applied to help with ponding.

- It’s not considered a “roofing system” – Per building code, a commercial roof can have a maximum of two roofing systems. A coating system can be installed over a building that already has two roofing systems without completely removing a full roofing system. Roof coating systems are considered by building code as “maintenance”.

Cons of a roof coating system

- Strict eligibility – the seams need to be in good/decent condition, there has to have been annual maintenance, and the insulation needs to be less than 25% saturated.

- No R-value – roof coating systems do not provide any significant R-value (less than an R-1).

- Gets quickly dirty – white or gray coatings will quickly get dirty when exposed to the elements. This doesn’t impact performance.

How is a spray foam roof installed?

How is a roof coating system installed?

What warranties does each roofing system come with?

Both roofing systems come with the same warranty options. You can get a 10, 15, or 20-year warranty. This warranty can be run through the roofing contractor or the manufacturer of the products.

Conclusion

If you don’t know what to do because of the fastener and adhesive shortage for EPDM and TPO roofs, hopefully, you know that a fluid-applied roofing system can be a great alternative. These roofing systems are self-adhering and usually don’t need anything to hold them down.

Below are two “Cheat Sheets” which will help you understand each system a little more.