Let’s be honest; we all want stuff done as cheaply as possible. Such as repairing the hole in the driveway, getting landscaping done, and replacing gutters.

But we also don’t want it done so cheaply that we don’t get the best value…the best bang for our buck.

What good is saving $20 on repairing the hole in the driveway with inferior materials if it’s going to fail again next year?

Today, we’re going to talk about existing flat gravel roofs and getting them repaired or restored.

And doing so in not the cheapest way, but the most cost-effective way possible.

Here are some topics we’ll go over:

- Why tearing off your flat gravel roof is an expensive option (if you can avoid it)

- Why roof coating systems are a very expensive option

- Why single-ply roofs aren’t the best option

- Why spray polyurethane foam is the best short and long-term cost-effective option

- What potential problems can happen when choosing spray foam

So you’re aware, West Roofing Systems has been in commercial roofing since 1979. We’ve repaired hundreds of flat gravel roofs and have seen what works (and doesn’t work) cost-effectively for our clients.

Let’s get started!

Why tearing off your flat gravel roof is an expensive option

This is self-explanatory, performing a complete tear-off is very expensive. You need to pay to remove the roof, transport all the materials to a landfill, and then install a new roofing system.

Most don’t know that it’s possible to install a new roofing system over what you already have.

You can avoid the complete tear-off if:

- You only have one roofing system installed. Per building code, you can have a maximum of two roofing systems installed. If you already have two installed, you will need to remove at least one roof before installing a new one.

- Your roof is in decent condition. Meaning the seams are intact and less than 20-30% of the roof’s insulation is saturated with water.

Roofing contractors determine the condition of the seams and the amount of wet insulation with visual inspections, core samples, and infrared surveys.

Let’s say your roof is in decent condition and the flat gravel roof is your only roofing system. Hooray! You can avoid the complete tear-off!

Let’s get into other options you have.

Why roof coating systems are a very expensive option

Some people think that a roof coating system is an inexpensive option for a flat gravel roof.

They think they can remove the loose gravel, power wash, do some seam treatments by embedding polyester mesh, and then install coating over the rest of the roof.

This would be true if it was a flat and smooth surface.

With foot traffic and weather beating down on your roof over the years, this will create indentations. To fill these and maintain roof slope, a large amount of coating is needed.

How much coating? It’s generally in the 5 gallon per square foot range.

Here’s a comment on YouTube from a coatings manufacturer answering a viewers question about the amount of coating needed on a gravel roof:

Now that we know how much coating per square foot, let’s do some math.

Say you have a 20,000 square foot roof.

A roofing square = 100 square feet.

Therefore, your roof is 200 roofing squares.

Roughly 5 gallons of coating is needed per roofing square.

Therefore, you’ll need 1000 gallons of coating.

Coating comes in 5-gallon buckets, therefore you’ll need 200 – 5-gal buckets.

A 5-gal bucket is roughly $50/each.

200 x $50 = $10,000.

NOTE: The above is based on an average gravel embedment of a tar and gravel roof. If the gravel is very coarse, it would take much more coating to make a complete water-tight coating system.

Even if the price of the coating came back to mid-2021 prices (let’s say $28), the cost would be around $5,600.

Extra insight: If there’s any ponding/standing water, you will have to install a tapered system (using the insulation to create the slope) which is time-consuming and expensive. Also, there is no increased R-value with a coating system. You are paying more for the materials upfront without including the labor.

Why single-ply roofs aren’t the best option

Some contractors say that they can remove the loose gravel, and then roll a single-ply roof over what you have.

This sounds like a simple, cost-effective solution.

The problem is that a cover board is needed first before the single-ply can be installed. This is to give the rubber sheets something to adhere to.

Another issue is the slope.

If there are low spots (which is expected since the gravel has created indentations), a tapered system will need to be added to the project’s scope of work.

Why spray polyurethane foam is the best short and long-term cost-effective option

Spray foam is the best option short-term because it can be installed with the least amount of preparation.

To install a spray foam roof, a contractor will remove and replace all the damaged membrane and wet insulated areas.

Then they will most likely use a wet-vac system to remove the loose gravel. Once that’s complete, spray foam can be installed.

Extra insight: spray foam is fluid-applied, which makes it easy to install around HVAC units, pipes, drains, etc. Other roofing systems need to cut around penetrations and make them watertight…a costly addition to the project.

Spray foam is the best option long-term for multiple reasons.

Reason #1 – increased R-value

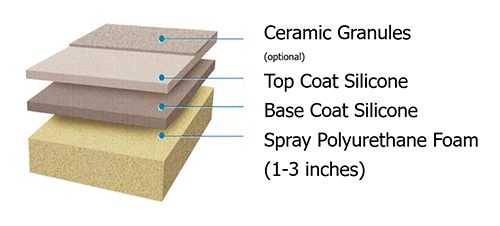

A spray foam roofing system is multiple parts: foam, coating, and granules.

Spray foam has an R-value of 6.5 per inch of thickness, which is the best R-value per inch of thickness of any roofing insulation.

This will reduce your future energy costs.

Reason #2 – spray foam is renewable

Once the coating that’s installed over a foam roof wears away, more coating can be added on and a new warranty can be granted.

For example, let’s say 1.5 inches of foam is installed and 20 mils of coating are installed over top. 20 mils of coating will get you a 10-year warranty.

In year 10, the 20 mils of coating will likely wear down to 7-8 mils.

A contractor can clean the roof and bring the 7-8 mils back to the original 20 mils. A new 10-year warranty would be granted.

Other roofing systems need to be torn off and replaced once their warranty ends, which is likely 2x as expensive as a spray foam recoat.

Reason #3 – Closed-cell insulation and repairs

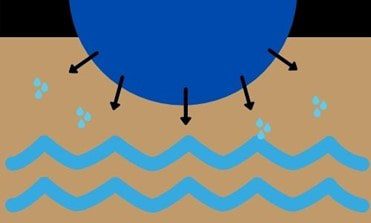

Spray foam is closed-cell. This means that if a hole occurs, the water will sit in that hole and not move. This is the opposite of traditional roofing insulation which is open-cell. This means that if water gets to it, the water will travel down and across, saturating more of the insulation.

It’s like dropping water on the corner of a paper towel. Water is only coming in one way, but eventually, the entire paper towel will be soaked.

The same thing can happen when there’s a small leak in open-cell insulation.

A repair on a spray foam roof is to dry the hole out, cut around it, and fill the hole with caulk. This is a very simple fix.

A repair with open-cell insulation could result in a very large area of insulation (and membrane) that needs to be removed and replaced. This is much more time-consuming and costly than the spray foam’s repair.

What potential problems can happen when choosing spray foam

The number one problem with spray foam is that there are bad contractors. Spray foam involves heating, pressurizing, mixing, and adjusting temperatures to spray good foam.

If the science isn’t right, your foam roof will not perform as it should.

Make sure if you go the spray foam route, that you check the company for Google reviews, look at their case studies, and have them provide a list of clients with whom they’ve done a similar project.

For example, get a list of clients that the contractor has installed a spray foam roof over an existing gravel flat roof.

If they give a list of spray foam roofs over other roofing systems, this doesn’t give you much confidence they will install your roof correctly. How a contractor handles specific existing substrates is a huge part of the process.

A secondary problem with spray foam is overspray.

Since spray foam is very lightweight, wind can carry it onto undesirable assets such as cars and windows. Make sure the contractor is aware of overspray and has windscreens or a booth to spray out of in case of windy situations.

Extra insight: Make sure the contractor will cover overspray expenses when you sign a contract.

Conclusion

Hopefully, you’ve learned at least one thing new about repairs on a flat, gravel-surfaced roof.

If you can, try and avoid the complete tear-off.

Then install the roof system that’s easiest to install.

Then install the roof system that will reduce your future expenses.

If you have any other questions about spray foam roofing, please check out our “cheat sheet” below: