SUMMARY: If you have an existing gravel built-up roof that’s old and leaking, don’t go the cheap route by putting a board over it and installing TPO. Doing so will cost less than a better solution (such as removing the rocks and spray foaming it,) but will create problems in the long run. In this post, learn the correct way to restore a gravel built-up roof, and the issues that can happen if you choose the cheapest route.

So, you’ve got a gravel-built-up roof with loose rock on top. It’s old, leaking, and you’re wondering what to do.

- You get a quote from one contractor who recommends removing the loose rocks and installing a spray polyurethane foam roof.

- Another contractor recommends leaving everything in place, mechanically-fasten a coverboard over the existing roof, and installing a TPO roofing system over the board.

Which solution is better for the building owner?

Installing the board and TPO will be the more cost-effective solution in the short term. The roof will be leak-free and cost you less than other solutions.

However, the board will move (either from foot traffic, wind, or other weathering events) and cause the loose gravel below to essentially grind through the board.

The board will lose its thickness, creating low areas on the roof that will collect water and potentially cause structural damage.

When water doesn’t run off the roof in a reasonable time, problems start to happen.

The water can get under seams, freeze, and create an opening when it thaws. Pooling water can cause the membrane to wear out quicker than desired.

Most warranties require the roof to have proper drainage. While it may have proper drainage in year 1, it may not have proper drainage in year 2.

Not having a proper slope could void your warranty.

Why is removing the loose gravel a smarter choice?

The smarter decision is to remove the loose gravel and install a spray foam roof.

Why?

You won’t have to worry about the loose gravel influencing slope. Once the roof is wet-vacuumed (basically vacuuming the rocks off the roof and cleaning the surface simultaneously), the gravel will be gone, and the surface will be clean.

Spray foam can be installed right over the cleaned surface.

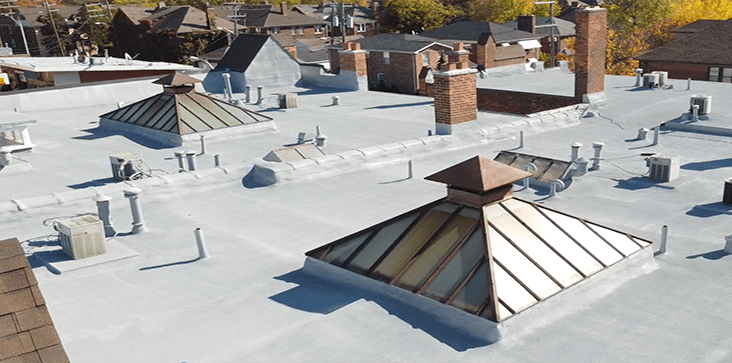

Here’s a finished photo of spray foam installed over an existing gravel built-up roof:

What other benefits are there?

- The spray foam roofing system is seamless.

There are no fasteners or seams to worry about as you would on a TPO roof. Fasteners can back out or be installed wrong. Seams can lose adhesion over time. These extra parts aren’t used when installing a spray foam roof.

This roof with vertical walls, HVAC units, curbs, and pipes has no seams…and not one fastener:

- Spray foam is fluid-applied and self-adhering

An issue with gravel-built-up roofs is the grainy surface they leave behind once the loose rocks are removed. Because spray foam is installed by spraying a liquid that rises 1-2 inches in thickness, it fills all the crevices and leaves behind a smooth surface.

Spray foam has tenacious adhesion to the surface below.

Being fluid-applied makes it easy to install around penetrations, such as skylights, drains, curbs, HVAC units, ductwork, etc. This greatly reduces labor hours when compared to TPO, which needs to be custom-cut to fit around every penetration.

- Spray foam also has the best R-value per inch of thickness compared to any other type of roofing insulation.

A higher R-value will reduce energy costs and the workload on your HVAC units.

The bottom line

Yes, a spray foam roofing system might slightly cost more than a board + TPO, but you’ll run into costly issues in the future.

When you combine the future problems TPO will create…with the extra benefits that spray foam provides, it’s clear the better choice is to go with foam today.

Our advice: Get quotes for both solutions. Compare the overall scope of work, cost, warranty, maintenance required after installation, and what the roof could look like 10, 15, and 20 years down the line.