When choosing the best roofing system for a large warehouse, spray polyurethane foam (SPF) is the best choice. The system offers several advantages over traditional roofing systems that make it suited for the demands of large-scale industrial spaces.

Here are 5 reasons why spray foam is the best option:

1. Superior Insulation and Thickness

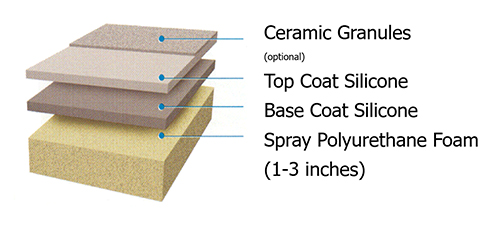

Spray polyurethane foam roofs are known for their exceptional thickness, typically 1 to 3 inches.

By industry standards, a “very thick” TPO sheet would be 80 mils.

80 mils = 8% of 1 inch.

A thicker membrane significantly reduces the likelihood of leaks caused by environmental factors such as branches, hail, or other projectiles.

The durability and resilience of SPF roofing ensures long-term protection for your warehouse.

2. Seamless Application

One of the standout features of SPF roofing is its seamless application.

Here’s a video showing spray foam being installed as a liquid, then turning into a foam:

Unlike traditional roofing systems such as TPO, EPDM, or metal roofing, SPF does not have seams or fasteners that can wear out or become damaged over time. This seamless nature eliminates common points of failure, ensuring a leak-free and reliable roofing system.

See how there are no seams or fasteners on this roof? The membrane is one continuous layer, even when going around penetrations or up walls.

3. Highest R-Value

R-value measures a material’s resistance to heat flow. SPF boasts the highest R-value per inch of thickness (R-6.5) among roofing materials.

This superior insulation is crucial for warehouses that store temperature-sensitive goods like food or electronics.

By maintaining consistent internal temperatures, SPF roofing helps reduce energy bills and minimizes the strain on HVAC systems, contributing to overall operational efficiency.

4. Renewable Warranties

SPF roofs offer the advantage of renewable warranties, which are particularly beneficial for warehouses intended for long-term use.

Typically, SPF roofing comes with a warranty of 10 to 20 years. The thickness of the protective coating determines the warranty length.

- 20 mil thickness of coating = 10-year warranty

- 25 mil thickness of coating = 15-year warranty

- 30 mil thickness of coating = 20-year warranty

At the end of this period, a contractor can easily renew the warranty by power washing the roof and applying a new protective coating. The process is cost-effective, costing only a fraction of the original installation, and can be repeated indefinitely, ensuring ongoing protection and peace of mind.

NOTE: You may wonder how the spray foam itself performs over time. Spray does not lose any performance measures over time. There are roofs we’ve done in the 1980s that still have the original spray foam on them. These roofs have been recoated 3-4 times and the original foam still performs great.

5. Ease of Maintenance

Maintenance is straightforward with SPF roofing.

Any nicks, cracks, or imperfections are easy to spot and can be quickly repaired with caulking or silicone coating.

This simplicity is a significant advantage over other roofing systems.

Plus, spray foam is closed-cell. Even if there’s a crack, the closed-cell nature will not allow water to pass through.

Inspecting every seam on a TPO or EPDM roof over a 500,000-square-foot area is extremely time-consuming, as is checking every fastener and seam on a metal roof.

SPF roofing’s ease of inspection, repair, and closed-cell nature translates to less downtime, lower maintenance costs, and a leak-free roof is damage occurs.

Conclusion

For large warehouses, spray polyurethane foam roofing offers unmatched benefits in terms of durability, insulation, warranty renewability, and maintenance ease. These advantages make SPF the best roofing system choice, ensuring your warehouse remains protected, energy-efficient, and cost-effective for decades.