We all want a roof that doesn’t leak, keeps heat/cool in, keeps pests out, and protects us from the elements. That was not the case for the US soldiers at the Jabala Military Base in Iraq in 2008.

The metal roofs in the barracks had aged and cracked, allowing animals, dust, moisture, and extreme heat to enter.

In Iraq, where the temperature regularly exceeds 100 degrees Fahrenheit, efficient HVAC is of the utmost importance, especially for military personnel.

With the roofs allowing extreme heat to enter, providing a comfortable environment was impossible.

The best solution was to install a thick, seamless material that seals the roof entirely.

In 2008, the U.S. Army Corps of Engineers called West Roofing Systems to install spray foam roofing systems.

West Roofing Systems has been installing these systems since 1979.

In the article below, learn:

- The importance of leak detection

- The problem with traditional roofing systems

- The benefits of a seamless roof

- And about the real-world application in Iraq

The Importance of Leak Detection

One of the most significant challenges faced by building owners regarding roof systems is the constant battle against leaks.

Water infiltration can wreak havoc on a structure, whether from harsh weather, wear and tear, or poor installation.

Pinpointing and repairing leaks can be impossible for buildings with complex roofing systems, such as ballasted (rock-covered) roofs or those with seams like TPO and EPDM.

That’s where spray foam roofing stands out — offering a seamless, watertight solution that helps eliminate leaks, even those that are microscopic and hard to detect.

The Problem with Traditional Roof Systems

Traditional roofing systems with ballasts, such as those using rocks or gravel, make roof maintenance and leak detection challenging.

With rocks covering the roof membrane, identifying leaks becomes incredibly difficult because there’s no clear way to see beneath the ballast to inspect the membrane.

This creates a problem for building owners who are trying to locate and repair leaks.

Similarly, roofing systems with seams, such as TPO and EPDM, present their own challenges.

While these materials are durable, any slight uplift in a seam — which may not be visible to the naked eye — can become a potential entry point for water.

Even the slightest breach can lead to leaks that are difficult to detect, requiring time-consuming and costly repairs to locate and fix.

Enter spray polyurethane foam, which is a game changer.

The Benefits of a Seamless Roof

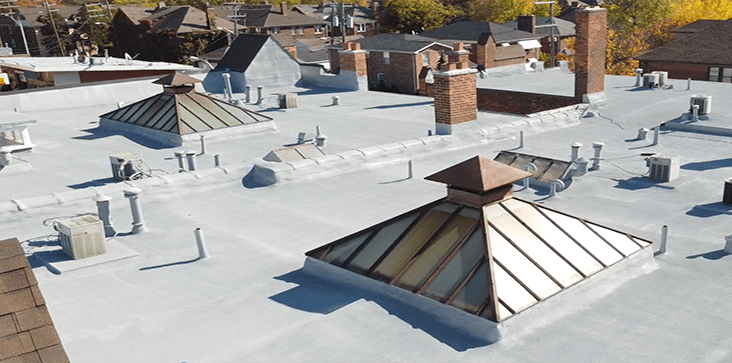

Spray polyurethane foam creates a continuous, monolithic membrane that adheres directly to the surface it is applied to, creating a seamless, watertight barrier.

This eliminates the risk of leaks from seams, cracks, or gaps that are common in traditional roofing systems. With spray foam, the roofing material forms a solid, smooth surface that effectively prevents water from infiltrating the structure, even at microscopic levels.

One key benefit of spray foam is that it increases the roof’s R-value, improving thermal insulation and reducing the amount of air that leaves through the roof.

This helps maintain comfortable indoor temperatures, particularly in climates with extreme heat or cold, and can reduce the need for energy-consuming HVAC systems.

But perhaps the most important advantage is spray foam’s ability to stop leaks, especially the hard—to—see ones.

Real-World Application: A Military Base in Iraq

To truly understand the benefits of spray foam roofing, it helps to look at a real-world example. One such project occurred at the Jabala Military Base in Iraq, where spray foam was used to rehabilitate six buildings with steep-slope roofs.

The buildings’ original transite panels, which had aged and cracked over time, allowed birds, bats, insects, and other pests to infiltrate the space between the drop ceilings and the roof. The damage also allowed heat to penetrate, making it nearly impossible to maintain comfortable interior temperatures.

During rainy periods, moisture also entered the buildings, causing further damage and discomfort.

One key reason the corps of engineers wanted foam on these buildings was that the existing roof contained asbestos and was fastened from the inside of the building through the roof. This left thousands of bolts extended through the roof and exposed to the elements.

We needed to cut each bolt off above the nut and encapsulate the asbestos with spray foam.

The only solution was spray foam roofing.

The crew from West Roofing Systems, including six employees from the United States and 16 local Iraqi nationals, applied a minimum of 1.25 inches of spray foam directly to the transite panels, covering 150,000 square feet across six buildings.

After applying the foam, they added two coats of silicone to protect the foam from UV rays.

The result was a seamless, watertight roofing system that conformed perfectly to the profile of the transite panels.

Customer Benefits

The transformation of the Jabala base’s roofs had immediate and long-lasting benefits:

- Eliminated Pests: The seamless membrane sealed any gaps or cracks, making it impossible for birds, bats, or insects to enter the building.

- Reduced Dust: The new roofing system also helped reduce the amount of dust entering the buildings, creating a cleaner and healthier environment for our troops.

- Moisture and Leak Protection: By completely covering the roof and creating a continuous membrane, the spray foam system eliminated moisture penetration and resolved the leakage problems that plagued the buildings.

- Improved Energy Efficiency: The additional insulation provided by the spray foam increased the roof’s R-value, improving energy efficiency by reducing heat transfer and helping the air conditioning systems perform better. This led to more comfortable living and working conditions for the military personnel stationed there.

Conclusion

Spray foam roofing offers unparalleled benefits for building owners looking for a durable, efficient, and effective roofing solution. Its seamless and watertight membrane ensures long-term leak protection, even for those microscopic breaches that traditional roofing systems can have.

Spray foam increases thermal insulation, reduces energy costs, and eliminates pests and moisture.

It is an investment that pays dividends in both comfort and long-term structural health.

Whether you’re dealing with aging transite panels, problematic seams, or challenging ballast systems, spray foam roofing provides a versatile and reliable solution to keep your building safe, dry, and energy-efficient for years to come.