I got a phone call yesterday, “Greg, our metal roof is old and leaking, and we’re thinking of ways to repair it. Cost is our #1 concern”

If this sounds like you, you’re in the right place!

In short, you have four options:

- Replace all screws and fasteners

- Remove and replace the entire metal roof

- Install a roof coating system over the existing metal roof

- Install spray foam over the existing metal roof

If that’s all the info you were after…great!

If you want a more detailed answer, please continue reading.

And just so you’re aware, this article has been reviewed and edited by a roofer/salesman with more than 30+ years of experience in the field.

Option 1 – Replace all screws and fasteners

Most metal roofs leak due to screws and fasteners wearing out or becoming damaged.

You can see this screw has backed out, which is creating a way for water to enter the building.

If you have a number of these, one option is to remove anything that looks suspect, remove the screw and fastener, and install a new one.

This is not a recommended repair option.

It would be very labor-intensive to inspect every screw to see if anything is suspect. Plus, a cracked fastener or a screw that’s backed out by 0.01 inches is going to be hard to find.

Keep reading, there are better repair options below.

Option 2 – Remove and replace the entire metal roof

The cost of labor and materials to install a metal roof will cost at least $15 per square foot.

Add in the labor to remove the existing metal roof and the cost to transport the materials to the landfill, and you may be approaching the $20 per sq. ft. range.

Starting fresh with a new roof is nice, but if cost is important, there are better options.

Option 3 – Install a roof coating system over the existing metal roof

If cost is important, this is your best option.

The ballpark cost for a roof coating system is $3 – $7 per sq. ft.

An elastomeric coating (meaning it can stretch) can be installed over an existing metal roof.

Coatings are fluid-applied by spraying or rolling the material over the roof.

Here’s a video of a silicone roof coating installation:

With coatings, there is minimal tear-off. Only the damaged areas get removed.

The first step to installation is to prepare the metal roof to accept the coating.

Preparation includes:

- Replacing any metal that could affect the coating’s adhesion or performance

- Power washing the roof clean

- Adhesion tests with different coatings

- Considering the use of a rust inhibitor primer

- Adding additional coating over the seams

- Adding additional coating over screws and fasteners

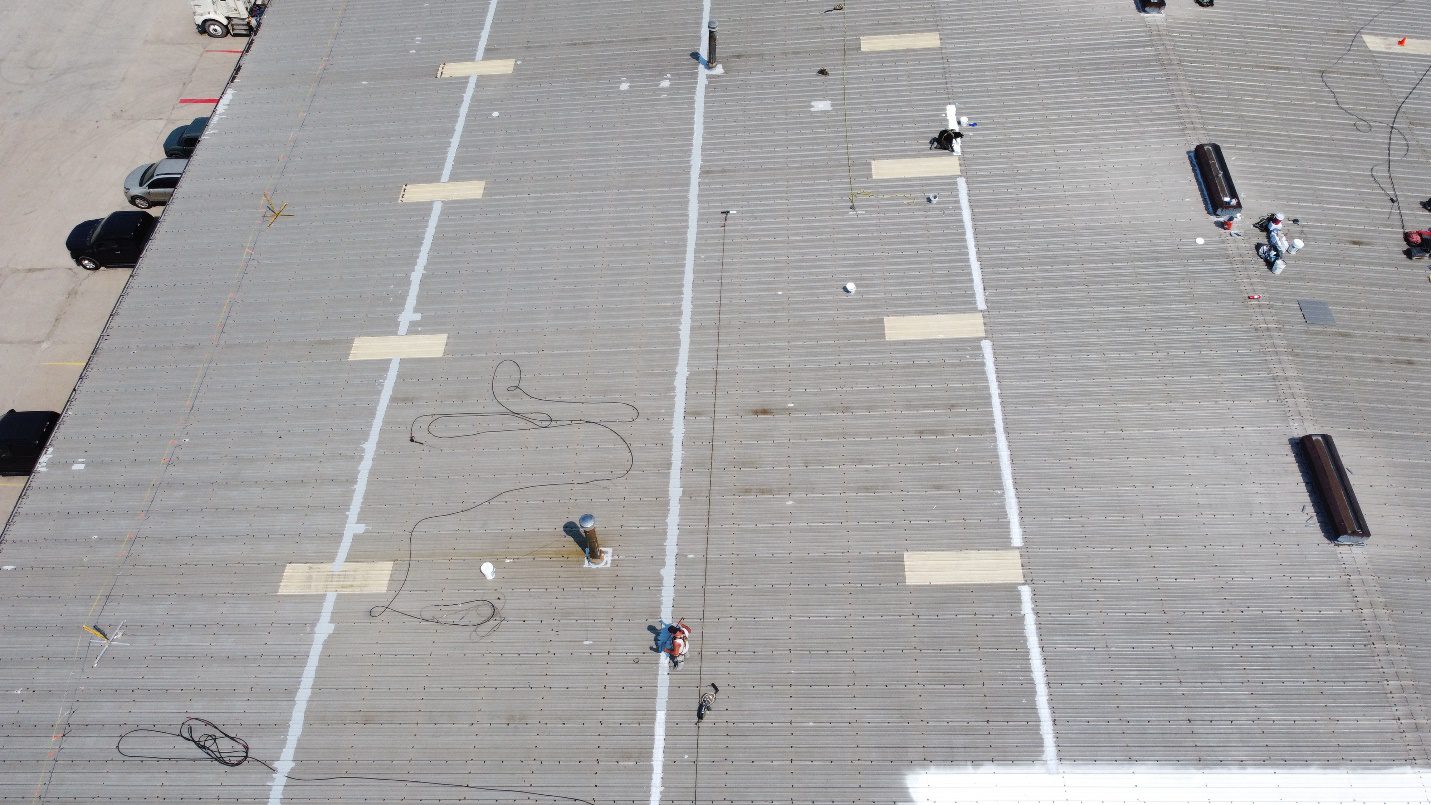

Here’s a photo of a metal roof being prepared for a coating system:

You can see there’s an additional coating (and perhaps scrim or fabric that’s embedded into that coating) to reinforce the seams.

Most roof coating systems come with 10-, 15-, or 20-year warranties, the length of which is determined by the coating’s thickness.

- For a 10-year warranty, 20 mils of coating would be installed.

- For a 15-year warranty, 25 mils of coating would be installed.

- For a 20-year warranty, 30 mils of coating would be installed.

The warranty is either granted by the manufacturer or the contractor, or some combination of both.

Here are some photos of silicone roof coatings over an existing metal roof:

Nature’s Garden (2021)

Artiflex (2021)

Option 4 – Install spray foam over the existing metal roof

Another great option is to install spray polyurethane foam over your existing metal roof.

Why?

It can also be installed over your existing roof (minimal tear-off) and has additional benefits that coating systems don’t have.

Here’s a start-to-finish video of spray foam installed over an existing metal roof:

You might wonder if you can spray foam over everything or if some areas need to be repaired first.

- If the roof is leaking because of a seam or fastener, you can foam over it.

- If there’s rust or you cannot walk in the area, then you need to repair the area before foaming it.

Here are some benefits of spray foam roofing:

Increased R-value

Unlike coatings, spray foam has a significant R-value. Spray foam has an R-value of 6.5 per inch of thickness, which will reduce your energy costs over the roof’s lifetime.

Depending on the current conditions of the roof, spray foam can pay for itself through energy savings.

Here is a link to Texas A&M University, which installed spray foam over its existing roofs.

TAMU recovered the complete cost of the roof application through energy savings in an average of 4.5 years.

Closed-cell Insulation

Spray foam has closed-cell properties. This means that if a crack or other type of damage occurs, water will sit in the crack and not move.

In open-cell insulation, if a crack occurs and water enters, water will expand horizontally and vertically, saturating a large area.

There are a few drawbacks to spray foam.

One, spray foam costs more than coatings. A spray foam roofing system costs approximately $5 to $10 per square foot.

Two, spray foam can only be spray-applied. If your metal roof is near an area where overspray is a large concern (such as a car dealership), coatings may be a better option.

What’s next?

Now that you know there are multiple options to repair your metal roof, your next step is to learn more.

Here are some case studies where you can see the full scope of work:

- Sharpsville Container – Learn how spray foam was installed over 4 different roofing systems, including steep slope metal, saving the client hundreds of thousands of dollars.

- MTD – Learn how 3 spray foam robots and a 14-person crew finish a 384,000 sq. ft. spray foam roof in 52 days.

- Colonnade Towers – A silicone roof coating system installed on a steep slope metal roof in Birmingham, Alabama.