So, your rubber roof is leaking and you don’t know what to do.

Rip it all off?

Install something over it?

You don’t want to rip it all off when a simple repair can do.

And you also don’t want to make repair after repair when a complete replacement is likely right down the road.

In this article, you’ll learn three repair options for rubber roofs. Each option depends on the roof’s current condition:

- Stripe (only) the seams with silicone coating

- Install a silicone roof coating system

- Install a spray foam roofing system

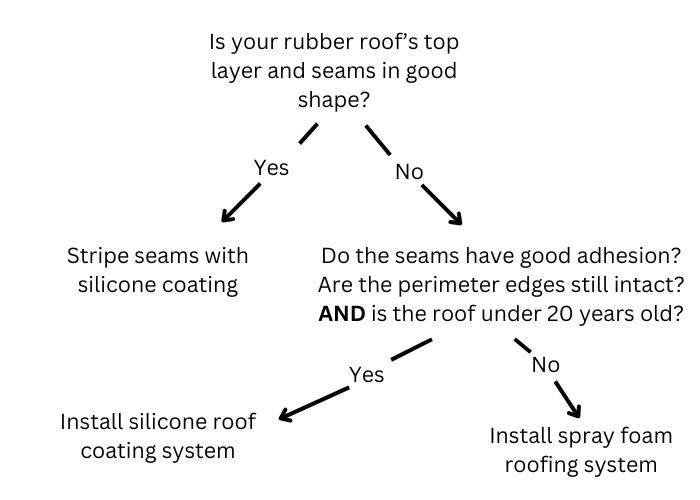

This chart can give you some direction before you read the details below:

Rubber roofs are popular for their low-cost material pricing and flexibility, but all roofing systems can develop leaks over time.

On a rubber roof, leaks are 99% caused by lost adhesion within a seam or a hole in the rubber.

Here are three effective repair options for a leaking rubber roof.

If the membrane and seams are in good shape, you might want to:

1. Stripe the Seams with Silicone Coating

If the rubber membrane is in good condition and the seams have maintained strong adhesion, a simple solution is to reinforce the seams using a silicone coating system.

This involves applying mastic, embedding mesh, and then covering the seams with a layer of silicone coating.

By reinforcing the seams, you significantly increase their strength and longevity, effectively sealing them against leaks.

Why it works:

- The silicone coating acts as a flexible and waterproof barrier.

- The embedded mesh adds structural support to prevent future separation at the seams.

- The coating is a barrier between the aged membrane and the sun/weather.

- This method can extend the roof’s life without requiring a full coating system.

This is an ideal solution when most of the roof is intact, but the seams show signs of lost adhesion.

NOTE: You might ask, if the roof is in good shape, why do anything at all? Striping the seams can reinforce the roof today and get you another 5 or so years before the entire roof needs to be coated. But once the seams rip apart, wet insulation happens, more of the seams come apart, and many other things lead to a much more expensive roofing solution.

But if the seams and membrane are in good condition and you want a long-term solution, you might want to consider:

2. Installing a Silicone Roof Coating System

If the seams have decent or good adhesion, the perimeter edges aren’t drying out, there’s no “tenting” (where the rubber doesn’t adhere to the walls anymore), and the roof is under 20 years old, installing a silicone roof coating system is an excellent long-term solution.

This process provides full roof coverage and addresses seams and any potential weak spots.

The basics of the installation include:

- Adhesion testing

- Identifying, removing, and replacing any wet insulation.

- Powerwashing the entire roof surface, possibly with a rinse cleaner.

- Applying a primer for better adhesion.

- Installing a bleed blocker to prevent asphalt bleed-through.

- Reinforcing the seams for added durability.

- Finally, installing a silicone coating per manufacturer specs over the entire roof to create a seamless, waterproof layer.

Why it works:

- Silicone roof coatings offer superior reflectivity, waterproofing, and a new (and renewable) 10-20 year warranty.

- This solution reinforces existing seams while creating a monolithic, leak-proof surface.

- It’s a cost-effective option that extends the life of a rubber roof.

This approach ensures that the roof is fully sealed and protected, offering decades of performance with proper maintenance.

NOTE: One thing that’s overlooked is financial predictability. With a renewable 10-20-year warranty, you can forecast future roofing expenses. You know that in 10, 15, or 20 years, a recoat needs to be installed (costing 33-50% of the original installation in today’s dollars). The recoating process can be repeated continuously.

If your rubber roof isn’t in decent shape, you might want to consider:

3. Installing a Spray Foam Roofing System

For rubber roofs where the seams are lifting, the perimeter edges are drying out, there’s “tenting” (where the membrane is no longer adhered to the walls), or the roof is over 20 years old, a more comprehensive solution is required.

In these cases, installing a spray polyurethane foam (SPF) roofing system is the best option. This process involves removing the existing rubber, installing a coverboard, and installing spray foam.

The basics of the installation include:

- Removing all the existing rubber material.

- Identifying and replacing any wet or damaged insulation.

- Installing a ½-inch coverboard over the roof deck for perfect spray foam adhesion.

- Apply spray polyurethane foam to the entire surface.

- Finally, a protective coating over the foam to guard against UV rays.

Why it works:

- Spray foam roofing systems provide excellent insulation (R-6.5 per inch of thickness) and creates a seamless, waterproof barrier.

- The foam conforms to the roof’s shape, eliminating issues with sloping, around penetrations, and anything else that’s on the roof.

Spray foam roofing systems are especially valuable for older roofs that need a complete overhaul and can offer long-lasting protection when installed correctly.

Want to see a Start-to-Finish video of a spray foam roof over an EPDM roof? Check it below:

By evaluating the condition of your rubber roof and choosing the appropriate repair method, you can ensure that your roof remains functional and leak-free for years to come.

Whether you’re looking for a minor repair or a full roofing system replacement, each option offers tailored solutions for different stages of roof wear and tear.

Looking to learn more? Here are some helpful resources:

- Video: Look at spray foam and silicone roof coating installations via West Roofing System’s YouTube Shorts channel.

- Case Study: Silicone Roof System – Learn how the silicone roofing system helps this school reach a critical year 11.

- Case Study: Spray Foam Roofing – Learn how spray foam’s versatility (going up walls and penetrations) made this job simple.