Specialty Applications

West Roofing Systems has in-house capabilities at our LaGrange, Ohio location for projects that require unique and creative solutions.

Our teams share their industry knowledge and ingenuity to work with customers on solving their facility problems.

We have a full-service, in-house metal shop, and full-time team members that can do ANYTHING literally to a commercial roof to stop leaks, influence slope, whatever needs to be done.

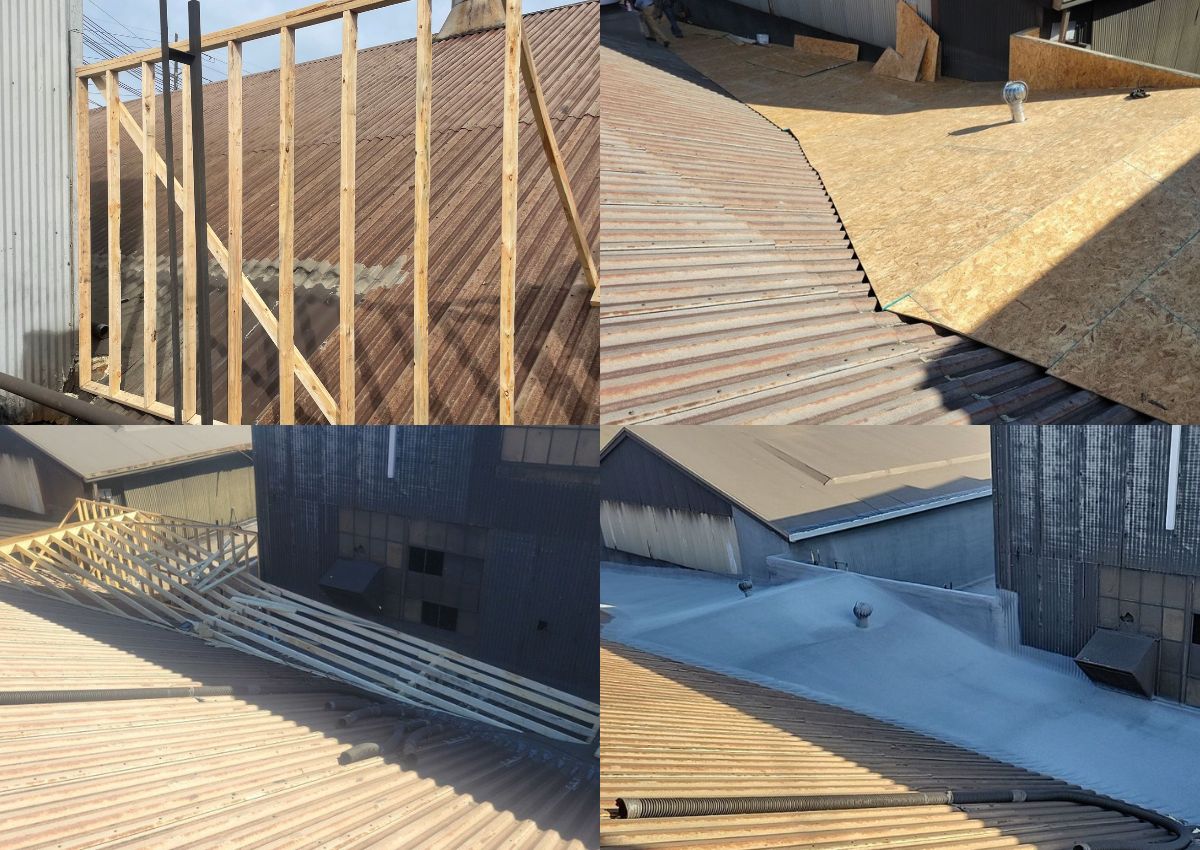

Water Diverter

The main problem of this project: The additional buildings created a “pit.” The pit was receiving water from four roof sections.

With only two drains and the amount of sand that escaped through the building, the drains quickly clogged. This created standing water in the “feet,” which allowed water to enter the building.

Adding drains was not feasible as there was no possible way to run piping in the building.

To eliminate this problem, we rerouted the four water routes with new downspouts, new gutters, building a wall, and a dormer. A custom-made 12-foot wall, custom-fit dormer with custom sloping out of wood, and foaming it all in was something innovative and creative.

The pit, surrounding walls, the new wall, and the dormer all received spray foam, coating, and granules.

Custom Snow Breaks

Ice was falling from the roof at Normandy, damaging the membrane.

We custom-built snow breaks in our metal shop to reduce the impact.

Whatever it takes to ensure your roof performs perfectly, we’ll find a way to get it done.

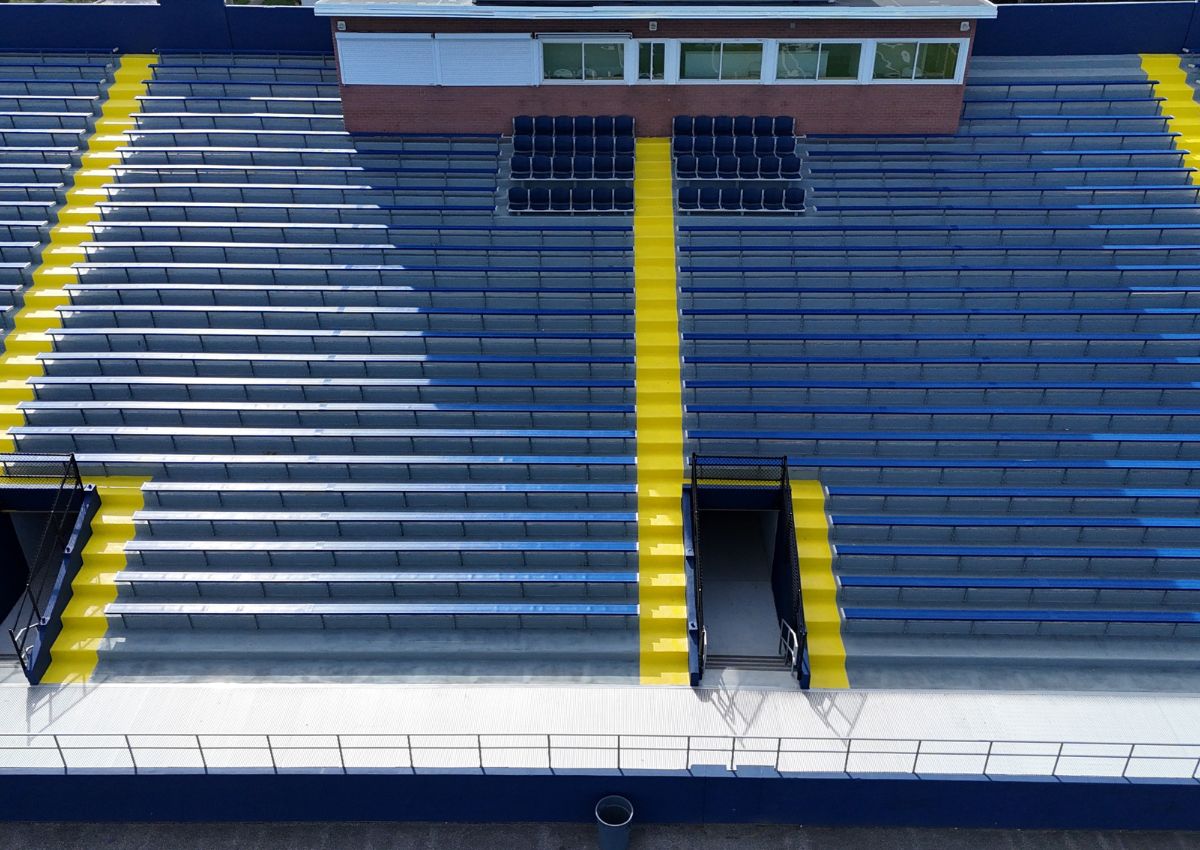

Roof Coating System Installed at Stadiums

We renovated 16,275 sq. ft. of concrete bleachers at Lorain's football stadium by removing the old seating, repairing cracks and damaged areas, and applying a protective urethane coating system.

The new coating creates a durable, slip-resistant surface that withstands weather and heavy use, helping the stadium remain safe and low-maintenance for years to come.

Silicone Coating for Exterior Walls

We applied a custom-color, high-solids silicone wall coating system to 12,314 sq. ft. of corrugated metal wall panels.

The project included surface preparation with scraping and pressure washing, sealing all wall penetrations, and applying a 10-mil-thick silicone coating in Mansard Brown for long-lasting protection.

The system was completed with neatly finished trim work, painted man doors, and comes with a renewable 5-year warranty.

Spray Foam Up and Over Vertical Walls

Because spray foam is fluid-applied and self-adhering, it can easily transition from a flat surface to up and over a vertical wall.

Walkways

Some roofs had a walkway system installed, but it was failing or falling apart. We can revamp those. Or perhaps nothing was there, and you'd like a designated walkway to guide students, workers, etc.

We can design and build that for you.

And integrate it into the roof system, ensuring the roof is leak-free and waterproof, and the walkway is sturdy enough for the intended traffic.

Custom-made Saddles to Create Slope and Drainage

The roofs at People's Services - Parkersburg were very unique. They were designed many years ago for military strategy.

The design created many flat areas and poor drainage.

We designed wood saddles with a proper slope and spray foamed them in, making a seamless, smooth transition from a flat roof to a vertical wall.

Drains with Chicken Wire and a Bird Basket

Some drains are expected to handle a large amount of water and can never clog.

Custom Casting Unit Pads

The customer wanted all existing unit curbs removed and to install a new 3’ x 10’ continuous unit curb built out of 4x4’s and ½” plywood, then covered with EPDM, which would make it impossible to lift all three units at the same time.

Our suggestion was to make them separate 2.5' x 2.5', which would make it easier to lift the units separately and also help water flow around and under the unit pad, and if any issues arise under the pad in the future. It would be easier to access.

We had the capabilities to construct the framing, metal forming, and installation of 84 unit pads.